Oh no, I hear you groan, not another wretched Cub and ARTF to boot! Well yes, a Thunder Tiger to be precise. If, like me, you do not have the time to build from scratch, these ARTF machines are mostly beautifully made and incredibly good value for the larger sizes.

Weight considerations

This one is intended for i.c. power, so the BIG question is: will

it finish up too heavy? An estimated figure from the manufacturer

refers to i.c. power of course, and may also be unrealistic. Starting

from here, however, a predicted electric weight can be obtained.

Once the kit is purchased, one can weigh the bits and firm up

the answer. An accurate weight budget can be an excellent discipline

and a challenge.

One always finds that the last ounce weighs 8 oz., however.

Why is this?

The fault is always ours. In my case, I assumed all sub-C nicads

weighed the same as my 1900's at 2.1 oz. each, but the 2400's

I fitted were 2.33 oz. and for 18 of these that is an extra 4

oz. I saved weight by using much lighter wheels than supplied,

a Jeti mini 7 Rx (full range but only 0.5 oz.) and Multiplex MX-4

micro-servos having as much torque as a standard servo at half

the weight. I also dispensed with a Rx. nicad and used an old

ESC which I had spare to run off 12 cells of the 18 cell flight

pack to produce a 5V supply. An expensive solution, but only 20

gms. and no charge or discharge problems. Finally a brushless

motor, but that is another story.

Choice of motor

Here I rely on Motocalc to assist. I was determined to have plenty

of power,

because there is nothing worse than being underpowered with an

electric aircraft. A Cobalt Astro with a gear box was the first

thought. This has been a very popular choice for medium to high

power aircraft and it would certainly have been a solution. However

I was doubtful about a gearbox because of the strange noises they

can produce and a belt drive, although quieter, was even heavier

and produced answers like 50W/lb from Motocalc which is a bit

marginal. I could not avoid the fact that a brushless motor would

be a huge improvement, especially an Actro.

These motors may not be unique but are almost without parallel as, with the larger sizes of Actro, the torque is so large and the revs so low that direct drive is entirely feasible, so no more gearbox problems. I chose the 24/5 to give the revs that I required and it weighed only 12.5 oz. compared with at least another 10 oz. for an Astro 40 and belt drive. It also provided 72W/lb and a 75% thrust/weight ratio using 18 cells, which guaranteed a powerful aircraft. Why a powerful Cub, I hear you say? Well power is always useful and sometimes essential, even if aerobatics are not planned.

The Actro is extremely unusual in that the magnets rotate on the outside while the armature windings are stationary on the inside. There is, of course, a whole range of Actro motors but the 24 and 40 types (the most powerful) are best suited to direct drive. The 40 type can handle up to 1.5 Kw, enough for a 20 lb model.

Another constraint, reading Motocalc, is getting the static pitch speed right. This should not be below 2.5 times the stall speed. Using larger, low revving props is more efficient in most respects with a relatively slow model. However it is easy to drop below the 2.5 figure and take off with great gusto only to lose out on thrust as the aircraft gains speed. With help from the software, a suitable choice of prop. should prevent this.

Costing

The Astro 40G is currently £170 & allowing £50

for the ESC brings it to £220.

The Astro 40 is £138, plus belt drive at £60 plus

ESC comes to £250.

The Actro 24/5 is £190 plus Actronic (40-32) controller

at £112 comes to £302

The brushless Actro looks to be an excellent choice, in view of

the weight saving and the extra power available.

Obtaining the motor

Obtaining the motor

No problem, surely. Well there is a U.K. retailer, Alan Fry, so

it seemed easiest to contact him. This I did and the motor soon

arrived off the shelf. It is a bulkhead mounting motor (why can't

they all be like this?) The existing bulkhead was not in the right

location and had to be extended forwards by a few inches. The

leads from motor to controller must not be extended and this placed

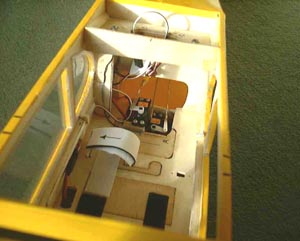

the controller right inside the pre-built fuz. (ARTF problems).

I cut open the fuz. from below and fitted the controller near

the bottom with

an air scoop to cool it.

Testing the motor

The motor growls and oscillates as it sorts out its timing, then

away.

Unfortunately dismay. Instead of the predicted current of 33A,

the reading was right off the scale (over 45A) and the revs. were

too high. Was my ammeter wrong and my tacho? surely not. But it

must be something I had done wrong. Eventually I tried a no-load

test and the revs were way above anything possible for a 24/5

motor, but just right for a 24/6. This had to be a wrongly-labelled

motor, even though it was hard to believe.

An e-mail to Kohler in Germany brought an immediate offer to exchange the motor and 10 days later I had another which performed correctly. The manufacturer said he had never known incorrect labelling to have happened before, but maybe there are models flying around inefficiently with the wrong motor attached!

Controller characteristic

The start-up arrangements are very foolproof, but you do need

to see the little red l.e.d. on the controller. I had to cut some

special spy holes so that I could see this l.e.d. from above,

as the controller was buried well below in the fuz. The controller

will not, of course, supply 5V but it does have a power

cut off (pco) facility. This does not involve a sudden total shut-down,

but is staged so that the power is progressively reduced which

gives plenty of warning but has the primary purpose of protecting

the nicads from serious over-discharge.

Other installation

matters

Other installation

matters

With a fuz. this fat there should be plenty of room inside. But

ARTF does limit the options available at this late stage. The

flight pack was split into 12 and 6 cell packs for convenience

and economy (The 12 cell pack was already in use with another

model).

Push rods were supplied for rear end controls, but I had never used these before as I had a long running infatuation with snakes. How about a change, I thought. I followed the instructions exactly (but one should not, of course). When I tried a push back test with the elevator, the push rod bent (failure!). Some mods soon put this right.

Range Test

I had broken some rules with the installation, but not wilfully.

The power leads

were long. The ESC/Rx lead had been extended, against Actro advice.

The Rx was neither dual conversion nor PCM. The relative locations

were good, however, with the ESC well forward and the Rx well

back. Larger motors seem to result in larger motor glitches, which

seems logical, and these seemed to be the limiting factor on range.

I was not really happy compared with other electric aircraft and

eventually moved the aerial outside the fuz., something I have

always been very reluctant to do for aesthetic reasons. This brought

an immediate improvement, so I reluctantly gave in.

Flying

The day dawned to perfection. Brilliant sun; breeze 5 knots. I

logged in for Stanpit. No excuses were possible but I felt very

ambivalent, I must admit: the usual first flight nerves for a

largish aircraft. Open the throttle to full, rapid acceleration,

tail up and off the ground well before the end of the runway (cricket

pitch?). An energetic climb-out followed and the Cub rapidly reached

my usual preferred ceiling. I throttled back, but still it seemed

to climb! I closed the throttle completely and it gradually descended.

Several leisurely circuits and

the Cub seemed very well mannered, with very realistic engine

noises. Must remember not to fly over the marshes! Prepare for

the landing approach in good time, because the expected duration

is a little unknown at this stage. Must avoid those Stanpit pot

holes! A very long flat glide in the light breeze took up 3/4

of the field and finally a nice tail-dragger touch down.

Then I remembered I had not tried the flapperons. They would have helped the landing, but the flap/elev. setting would probably need tweaking anyway. Something to sort out on the next flight.

In conclusion

In conclusion

Very pleased with: Not overweight (24 oz/sq.ft.).

Plenty of power (72W/lb.).

Handles well in the air.

Looks good (unless you are tired of Cubs!).

Not so pleased with: Have to remove wings & struts to fit

new batteries.