|

|

||||||||||||||

|

Christchurch and District Model Flying Club |

|

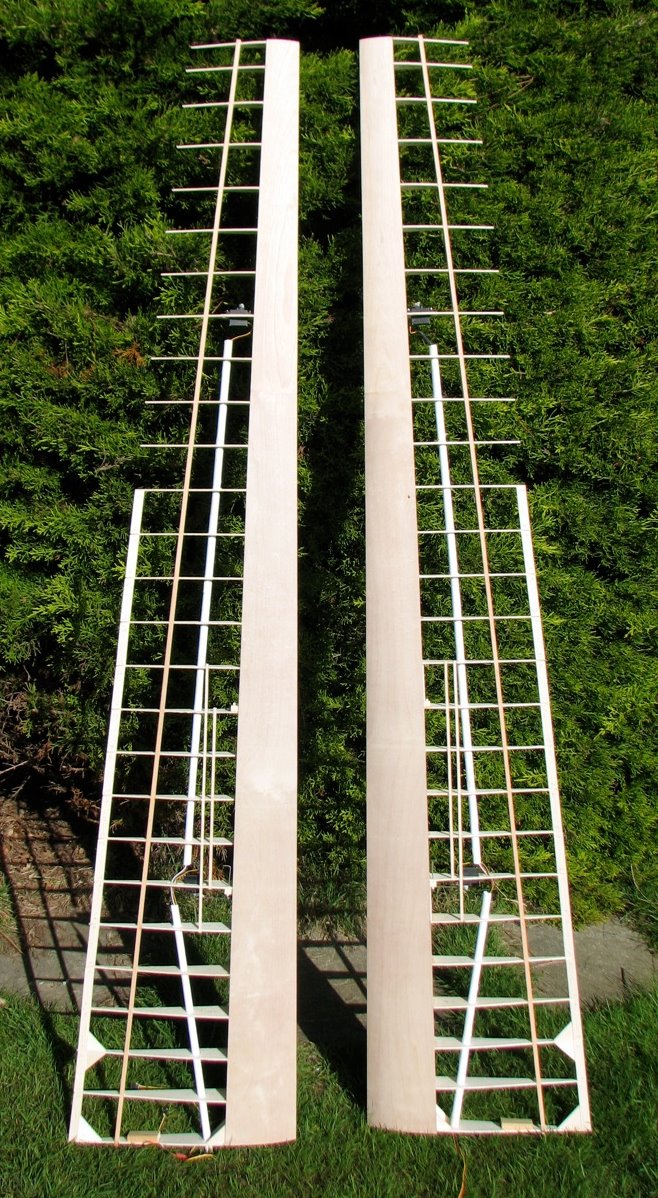

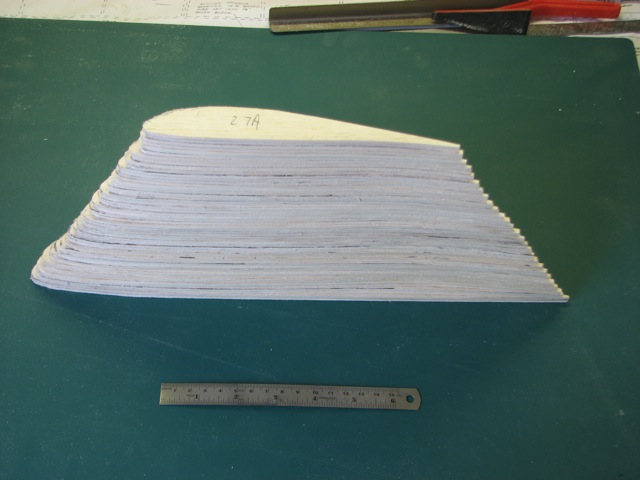

to sandwich, to cut out or to get them laser cut? I make that 26 or 27 ribs for one Falke wing: I wrote “Tell all Trevor, how did you do the ribs - sandwich method? The square-cut ends look suspiciously neat for that approach” and his reply is below. |

|||

|

|||

|

Apart from the cranked T.E. at rib 3 and the angled tip rib all the other ribs are equally spaced on a straight taper so I reckoned the sandwich method ought to work okay. I chickened out and made intermediate templates out of 1/16 ply, with a view to cutting the ribs in three batches. However, having done one batch of 6, the ribs needed so much individual fettling that I abandoned the method and did all of them separately. The process used was: 1. Trace the profile 2. Prick through onto the balsa 3. Join the dots 4. Cut out slightly oversize 5. Sand to match the original profile drawing 6. Draw round it 7. Repeat steps 4 and 5 8. Repeat steps 1 to 7 - twenty six more times! Some ribs - the three nearest the root and those supporting the outrigger wheels - are shown on the plan as 1/8in ply. However, I have cut them all from 3/32 balsa and will apply 1/32 or 1/16 ply doublers where I think they might be needed. I'm also wondering about cutting lightening holes? (the advice was not to bother - Ed) Because of the full depth spar, the wing ribs need a slice taken out of the middle. A few of the profiles have the spar position marked on them but not all, and I don't see how the cut lines can be marked accurately just by reference to the plan view. So I was thinking of marking up those where I do have the info, then using a sort of sandwich method to mark the spar position top and bottom on the intermediate ribs as best I can. Then my idea was to cut free the front sections of the reference ribs, trim their noses to allow for the leading edge then place the spar rear-face-down on the bench and glue on these front rib portions vertically. With a straight edge resting across the leading edge of these three or four reference ribs, I hope I can then cut and fit the front sections of the intermediate ribs whilst keeping the leading edge straight. One of the spars has a slight bow so I was thinking of keeping it flat on the board and carry on building the leading edge portion of the wing all the way to applying the leading edge sheeting (1/64 ply) in the hope that this would then hold the spar straight for building the rear portion of the wing. Does any of this make sense to anybody?! Trevor |

|

|

|

[Home] [Chairman's Chatter] [Editorial] [Bring a Model] [Paint Mixing] [Fly Diary] [DIY Electronics] [S-B Crusader] [Bumble Bee] [Falke ribs] [Guppy] |