|

|

||||||||||||||

|

Christchurch and District Model Flying Club |

|

My return to slope soaring and the Filip 600 Sport by David shires

One year ago I was at home on a rainy day thinking “I could do with a hobby that gets me outdoors and away from work, teenage children and DIY”. I sold my last boat four years ago and bought a plastic kayak which is great fun on holiday and in August when the sea is warm. Then a bright idea struck me. I could return to my lost hobby of slope soaring which I originally embarked upon over twenty five years ago. The only glider I kept was an Alpina, 4.4 Kg and 4.2m span. I dutifully joined C&DMFC and last Easter took my Alpina to the picnic site. A friendly fellow glider guider launched it for me and I circled it around for 15min before making a reasonable landing courtesy of the pop up airbrakes. This convinced me that it was no use for the local airstrip at Barton-on- Sea, and that I could never easily fly solo as launching the Alpina required a rapid sprint culminating in an athletic javelin throw. I therefore resolved to sell the Alpina and buy another glider. A few weeks later I purchased an Easy Glider plus a DX6i outfit. This has proved to be a marvellous investment as the Easy glider is ideal for Barton and so easy to fly! My only disappointment with the Easy glider is that the roll response time is measured in minutes rather than seconds. During August I acquired an X-it to aid with the excavation of Barton cliffs. However, I was still not a happy pilot as although the X-it has a super roll rate and is very manoeuvrable, I secretly desired a moulded glider. The only problem was cost and fragility. I discovered an internet supplier [Puffin Models] who sell RCM Pelikan gliders , made in Czechoslovakia. I selected a Filip 600 Sport which is a 2m semi-aerobatic soarer with very rigid foam/veneer wings and an epoxy cloth fuselage. There is a YouTube video of this flying and this convinced me to buy one. Terry Antell did advise me that the fuselages are ”thin as fag paper” but I went ahead anyway as epoxy cloth mouldings are very flexible and resilient. The cost is only £127.95 plus carriage as opposed to £250 or more for a moulded glider e.g. a Whisper or Luna etc.

On receiving the box I noted the slogan “Genuine Czech quality – just open the box!”. On inspecting the contents I was pleased to discover a pair of nicely made and covered wings plus tailplane and rudder together with the sleek but thin fuselage. I ordered 2 x Hitech 85mg for the ailerons and 2 x 325hb for the rudder/elevator. NOTE: I also bought a Ripmax battery checker which proved to be faulty as the exit wires gave an intermittent short circuit. This would have been disastrous in flight. I returned this to Stan Yeo [Phoenix Models], who sent it back to Ripmax. I have not had a reply from Ripmax but Stan Yeo said that he would credit the cost from my next order. Don’t buy one of these, the Fusion versions from CH4 models are better. Construction Wings

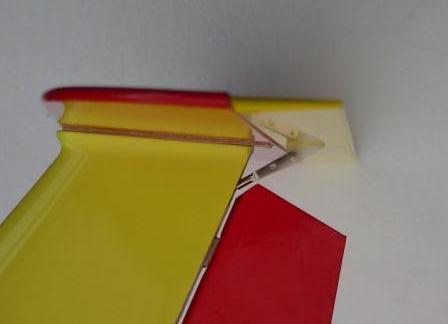

The servo apertures must be cut out of the wings carefully, lined with thin ply and the servos fixed with glue or double sided tape and wedges. The aileron horns are a stick on job. The servo covers are thin GRP mouldings which are simply taped on. The wings locate in the Fuz by means of two short dowels. I decided to glue two Al tubes in first so that the sacrificial dowels can be replaced in the event of a bumpy landing. The wings have the usual steel rod joiner with tubes already installed and attach to the Fuz with two plastic bolts.

Fuselage The first job was to strengthen the forward end with GF tape and slow epoxy. I made a balsa battery box and shaped this to fit inside the nose.

The servo mounts are again thick balsa with ply tops. This whole assembly ensures a very strong front end and wing seat area. The tailplane was reinforced where it sits on the fuz with thin ply and is easy to fit being held in place with two plastic bolts. It can be removed for transport.

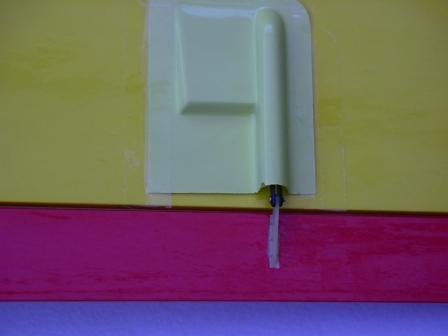

Glue in the cables and rudder post and the tail end is almost complete. The hatch cover was a problem. The manufacturers fixing method is useless.

I opted for an internal rubber band which attaches to a hook on the servo tray. This provides a flexible sliding fit and will give during a rough landing.

Controls The control cables were held in place with cut white foam carefully pushed down the fuz. This prevents control slop and also helps to damp tail “whiplash” when landing. The servos and cable support blocks are easy to fit and all the metal clevises were soldered for strength. There is plenty of room in the fuz for two standard servos and a two piece Spektrum 6200 Rx.

Completing this ARTF kit is certainly not a job for just a couple of evenings if done properly. The end result is though very pleasing. The all up mass is about 1.3Kg. Flying I ventured up Butser hill on an overcast and drizzly day to test fly the 600. It flew away nicely in the very light wind but required a lot of up elevator. I removed lead from the nose which improved this. The flight characteristics are smooth and stable with positive and progressive control responses. It will perform an axial roll after a short dive. The airframe is clean and efficient giving a flat glide helped by the SD7037 airfoil which has a touch of camber to give good lift. A touch of down elevator sees the 600 gain speed rapidly but it will fly fairly slowly for landing and it does not tip stall too easily. I would only recommend this glider for use with a decent computer Tx so that the control throws can be set precisely together with aileron differential, exponential rates and spoileron landing set up. My last [textbook] landing saw the 600 stopped dead by a large clump of grass. The only minor damage was that the rudder post sprung cleanly away from the fuz where the epoxy had not adhered well to the moulding interior surface. This was subsequently easily relocated with superglue. The front end showed no injury vindicating my reinforcing techniques. The inside surface of the fuz must be abraded before using epoxy, otherwise the adhesion is poor – I forgot to do this when fitting the rudder post. Conclusion I would recommend this glider as a viable alternative to a pricey moulded model. Its handling and looks are good and it will fly in very light lift or speed up when required. It can be built to withstand rough landings and the foam wings are strong and tough. It will transport in the original box. I look forward to further flights when we have some good flying weather.

|

|

back to contents |

|

[Home] [Chairman's Chatter] [Editorial] [Free Bee] [AGM Minutes] [BARCing] [Bring a Model] [Duct Tape] [Paint Mixing] [Quiz Night] [Slope Soaring] |